What tests are required?

Electrical testing before “livening” is essential to make sure the work has no hidden faults and is safe to connect.

- Testing

Overview

One of the most important and fundamental responsibilities of an electrical practitioner is having the skills, knowledge and understanding to properly test your work.

This expertise is what differentiates a professional licensed practitioner from an everyday person. As a licensed person you have been granted the right to carry out restricted work that others cannot do. These people are relying on your skills, and you in turn have an obligation to be competent with testing procedures.

Testing is one of the most important parts of the job, but it isn’t hard or time consuming.

What requires testing

All prescribed electrical work is required to be tested whether it’s:

- following repairs to an appliance

- replacements or repairs of fittings

- additions, alterations, rewires, new and extended circuits

- mains work, PV photovoltaic, medical, hazardous, mining, etc.

What tests are required

This always depends on the type of work. For example, mains work installation would involve different risk factors than repairing an appliance, so different or additional tests would be needed.

However, many of the underlying fundamental principles and individual tests remain the same though even when the procedures or reasons for testing may vary.

It’s important to have a good understanding of these fundamentals, including;

- how to drive your test instruments

- interpreting what the results mean and

- how to carry out the tests.

You also need to be familiar with these 2 testing standards:

- AS/NZS3000:2007 section 8 - verification

- AS/NZS3017:2017 Electrical Installations – verification guidelines.

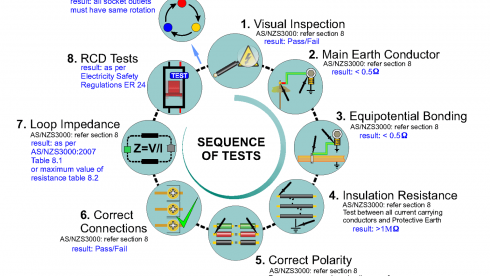

Tests for an installation

For the scope of this answer we are looking at the minimum tests required on an installation as per AS/NZS 3000;2007. Competency in these basic tests would give you transferable testing skills across the more specialised High Risk areas of the industry. Competency in these basic tests will require the right test equipment, practice and knowledge.

Resources for this are listed below.

AS/NZS 3000:2007 section 8 testing requirements

Visual Inspection. - Use the checklist given in Clause 8.2.2

| Earth Continuity Test | 8.3.5 |

| Insulation Resistance | 8.3.6 |

| Polarity Test | 8.3.7 This test completes the Active / Neutral Transposition Test Neutral not switched |

| Correct circuit connections Test | 8.3.8 This test completes the Neutral / Earth Transposition Test Active and Neutral belong to the same circuit. |

| Earth Fault Loop Impedance(EFLI) | 8.3.9 |

| Operation of RCD’s Test |

8.3.10 |

Carrying out tests

Testing can be broken down into a few basic steps:

- Visually inspect all the work. Are all the circuits terminated? Is it all safe?

- Pre-living test - the recommended sequence is listed in the table above. All these tests can be done without the power, supply except for the RCD. and EFLI tests. Note the EFLI can be calculated without power supply available in some circumstances.

- Before any live testing check again:

- Have you replaced the MEN link?

- Visual check again, others may have done work you don’t know about since step 1

- Carry out “live” testing of the RCD and the EFLI test.

- You can also reconfirm while the installation is “live” the polarity & correct circuit connections. Check switchboard labelling is correct, functionality and load tests on fixed wired appliances.

Resources available for instruction on electrical testing

If you feel you need to learn more about testing, or you want to learn how to use that flash meter you have just bought, then see these recommendations:

- approved competency programme providers:

- some will do separate testing professional development courses

- contact them directly or through your wholesaler, or check online

- if you’re an employer think about putting your employees or at least some of them on a testing course so they passon the skills to others

- ask your boss if you can go on a testing course

- some meter equipment suppliers offer training, contact them directly or through your electrical wholesaler

- electrical industry training organisations

- technical Institutes

- online videos and instruction on electrical testing (relevant to AUS/NZ standards and regulations)

- Electrical Wiring Practice (Volume 1) McGraw Hill education.